I am looking forward to see if any other users on the boards have direct experience and will be able to enlighten us both. The more the complex work that they will be doing the more likely that the 4000m will be able to render it quicker. I am sorry that I not more of help, without knowing the type of projects your colleagues will be working on, I really can't say if they will notice much of a difference. This will mean that the 4000m should be able to render your drawings faster than the 2000m. The big difference between the cards is that the 4000m has a 256 bit memory interface while the 2000m only has a 128 bit interface, and the 4000m has 336 cores compared to the 182 cores on the 2000m. Here is a link where you can compare the GPUs to each other.

MAGMASOFT PARALLEL SOFTWARE

I am not familiar with MagmaSoft, but drawing software tend to have fairly demanding system requirements so the Quadro 4000M may be the better choice.

The stats of the two GPUs are fairly different. Moreover 2000M works extremely fine on M4600.Īnything else that you want please reply.

MAGMASOFT PARALLEL INSTALL

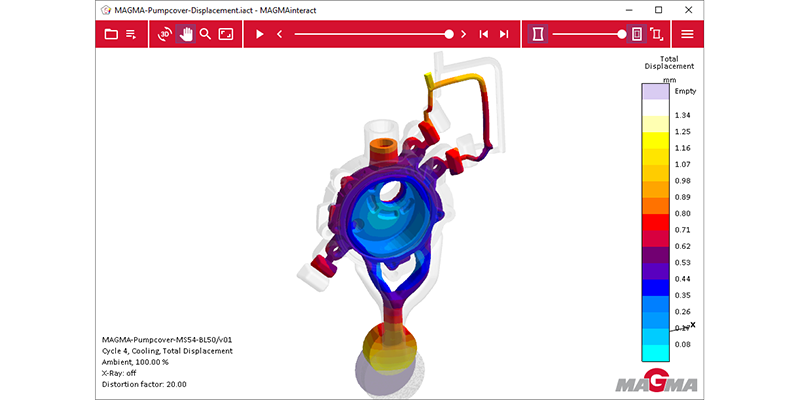

Yes, 2000M only available on the M4600 because of the size of the display, normally on a big laptop because of the size and space, advance graphic card can be install but system with small shape and size doesn’t has the capacity for that so the lower version of graphic card that is suitable for the system is installed in particular systems. A 3-D model of the pattern or part is created and simulations are run to find potential problems, of which porosity level, turbulence in the gating system an air entrapment are just a few. The Quadro 4000 is based on the previous Fermi flagship design, the GF100 (also used on the GTX 480, GTX 470 and GTX 465, as well as its higher Quadro siblings 60), but with a significant number of texturing units disabled (the Quadro 4000 has only 256 CUDA cores versus 448 CUDA cores in the GTX 470 and 480 CUDA cores in the GTX 480) and only a 256-bit DDR5 memory bus (versus 320-bit in the GTX 470 and 384-bit in the GTX 480). MAGMASOFT is solidification modeling software designed to optimize the casting process by simulating it on a computer. Soon, the MAGMASOFT ® 5.4 user interface will also be available in Chinese and Portuguese.īy systematically applying Autonomous Engineering, MAGMASOFT ® 5.4 supports a fast product and process development, optimized process and tooling designs as well as a robust process layout with maximum reproducibility of quality.I am Nikhil_ R from Dell Social Media and Communities teamĪs far as performance with the Quadro 4000 is much faster than Quadro 2000, this is because the Quadro 2000 is based on an under clocked GeForce GTS 450, with only 192 CUDA cores and only a 128-bit DDR5 memory bus. A direct upload of support requests to MAGMA’s support through the website is also possible. The online help system now allows an integrated opening of videos and tutorials from the website. By saving your login credentials in MAGMASOFT ®, the customer support area of the MAGMA website is now directly available from within the software. The new release is now fully integrated with the MAGMA website. Through the extension of the MAGMAlink module, any geometry and all results from MAGMASOFT ® can now be used for forming simulations with Simufact ( further details). For example, with a 16-core license, up to 8 virtual trials can now be calculated in parallel, which can lead to a significantly faster time to solution. In MAGMASOFT ® 5.4, the Parallel Design feature facilitates the parallel computation of several simulations (virtual trials) within a Design of Experiments or optimization, dependent on the number of available CPU cores. The consideration of the available machine capacity (PQ 2 diagram), the venting conditions and the complete thermal balance in the die, which are all critical for casting quality, can be evaluated at the earliest stages of process and tooling design. This enables the optimization of dosing parameters, dwell times, plunger velocities, and switching points. With these new features, MAGMASOFT ® 5.4 enables the detailed investigation of the dosing process and the shot profile considering the shot chamber geometry (Fig.

The new solver can simultaneously calculate different flow models (such as the flow through cooling lines during filling of the casting) while also supporting flexible boundary conditions (plunger movement, squeezing).

MAGMASOFT PARALLEL FREE

A new algorithm for the filling process in high pressure die casting considers the special requirements of the process on the description of the free surface of the melt, the metal viscosity, and the prediction of air entrapment for improved result quality. With the innovative TAG-meshing ( True Adaptive Geometry), MAGMASOFT ® 5.4 offers new possibilities for the flexible, local meshing of the geometry. A major advancement in the new version is the extensive support of the development for the component, the tooling and the process setup of high pressure die casting.

0 kommentar(er)

0 kommentar(er)